JPW series- NSF listed string wound water filter cartridge

JPW series string wound filter cartridge is certified by NSF since 2015, using best material and improved Japanese standard winding method, with higher efficiency and dirt holding capacity, ideal for drinking water purifier as sediment filter.

Inquire Now

Specification

STRUCTURE

String wound filter cartridge consists of multi-hole frames wound closely with textile fibers. Diverse kinds of filtering precision can be realized by controlling the winding density. As the outer bore diameter is larger than the inner one, the filter cartridges have a good deep-level filtering capability. JP series has straight multi-holes from the surface to the inner core, allowing maximum dirt-holding capacity and lowest pressure drop. The holes are now with slope design (25micron -200micron), creating swirling flow in the filter housing, which prevents particles from settling at the bottom and provides more benefits to the water. Various micron rates and sizes are available: 1micron, 5micron, 10micron, 25micron, 50micron, 100micron, 2.5"x10", 2.5"x20", 2.5"x30", 2.5"x40", 2.5"x50", 4.5"x10", 4.5"x20" etc.

The whole JPW series filters has been certified by NSF to the standard of NSF/ANSI 42.

FEATURES

• NSF listed for ANSI 42 standard

• Through slope holes create real depth filtration and swirling flow

• Large flow and small pressure loss

• High dirt holding capacity and long service life.

• Pure, clean material, no silicon, no fluorescence agent and no oil.

MAIN TECHICAL SPECIFICATION

• Dimension: Outer diameter Ø63±1mm Inner diameter Ø 28mm or Ø 30mm

• Maximum operating Pressure: 0.5MPa (72.5psi)

• Maximum operating Temperature: 60℃(140℉)

TYPICAL APPLICATIONS

• Residential water filter

• Food & Beverage

• Pre - RO

• Pharmacy & Hospital

• High quality industrial liquid filtration

• Other applications

TABLE 1

FLOW OF FILTER CARTRIDGE

The recommended flow for the filter cartridges in service is shown in the table (L/h for a 250㎜ filter cartridge)

Notes:

1. The flow of each 250mm(10inch)filter cartridge should not exceed 1200 L/H (317G/H), otherwise its precision may be affected.

2. The flows shown in the above table are only the recommended values. The actual flow of the filter cartridge in service may change due to the liquid nature, temperature, the nature of the eliminated particles, the contents of the particles, etc.

3. It is recommended that a new filter cartridge used in the first time should work under a pressure drop of 0.1 - 0.3 bar (1.45 – 4.35psi ), while the final pressure drop for the filter cartridge exchange is set at 2.5 bar. For the filter cartridge whose precision is lower than 10μm, the pressure drop for the filter cartridge exchange had better be set at 1.0 -1.5 bar (14.5 – 21.8psi).

TABLE 2

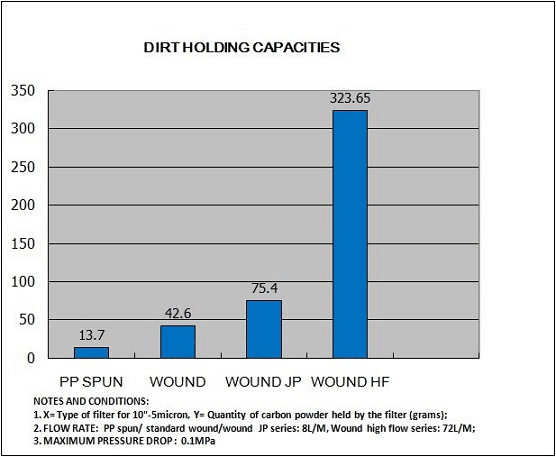

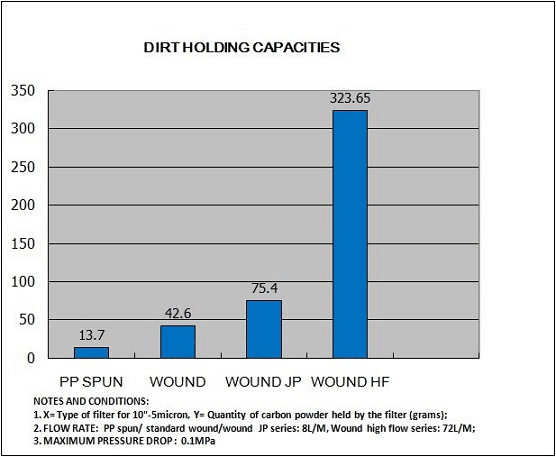

DIRT HOLD COMPARISON

TABLE 3

ORDERING INFORMATION

SF W 20- 5 P 63 P 28 JP W

A B C D

NSF link

http://info.nsf.org/Certified/DWTU/Listings.asp?Company=C0243330&Standard=042

Raw material will be tested carefully assuring consistant quality. Following pictures are taken from our laboratory.

String wound filter cartridge consists of multi-hole frames wound closely with textile fibers. Diverse kinds of filtering precision can be realized by controlling the winding density. As the outer bore diameter is larger than the inner one, the filter cartridges have a good deep-level filtering capability. JP series has straight multi-holes from the surface to the inner core, allowing maximum dirt-holding capacity and lowest pressure drop. The holes are now with slope design (25micron -200micron), creating swirling flow in the filter housing, which prevents particles from settling at the bottom and provides more benefits to the water. Various micron rates and sizes are available: 1micron, 5micron, 10micron, 25micron, 50micron, 100micron, 2.5"x10", 2.5"x20", 2.5"x30", 2.5"x40", 2.5"x50", 4.5"x10", 4.5"x20" etc.

The whole JPW series filters has been certified by NSF to the standard of NSF/ANSI 42.

FEATURES

• NSF listed for ANSI 42 standard

• Through slope holes create real depth filtration and swirling flow

• Large flow and small pressure loss

• High dirt holding capacity and long service life.

• Pure, clean material, no silicon, no fluorescence agent and no oil.

MAIN TECHICAL SPECIFICATION

• Dimension: Outer diameter Ø63±1mm Inner diameter Ø 28mm or Ø 30mm

• Maximum operating Pressure: 0.5MPa (72.5psi)

• Maximum operating Temperature: 60℃(140℉)

TYPICAL APPLICATIONS

• Residential water filter

• Food & Beverage

• Pre - RO

• Pharmacy & Hospital

• High quality industrial liquid filtration

• Other applications

TABLE 1

FLOW OF FILTER CARTRIDGE

The recommended flow for the filter cartridges in service is shown in the table (L/h for a 250㎜ filter cartridge)

| Micron Rate(μ m) | Viscosity | ||||

| 1cs(water) | 30cs | 60cs | 120cs | 250cs | |

| 0.5 | 70 | 60 | 40 | 25 | - |

| 1 | 150 | 90 | 60 | 40 | - |

| 3 | 300 | 120 | 80 | 50 | - |

| 5 | 500 | 170 | 120 | 60 | 45 |

| 10 | 800 | 300 | 140 | 70 | 60 |

| 20 | 1100 | 540 | 220 | 100 | 95 |

| 30 | 1200 | 670 | 300 | 150 | 130 |

| 50 | 1200 | 880 | 440 | 180 | 160 |

| 75 | 1200 | 1200 | 690 | 230 | 200 |

| 100 | 1200 | 1200 | 750 | 270 | 220 |

1. The flow of each 250mm(10inch)filter cartridge should not exceed 1200 L/H (317G/H), otherwise its precision may be affected.

2. The flows shown in the above table are only the recommended values. The actual flow of the filter cartridge in service may change due to the liquid nature, temperature, the nature of the eliminated particles, the contents of the particles, etc.

3. It is recommended that a new filter cartridge used in the first time should work under a pressure drop of 0.1 - 0.3 bar (1.45 – 4.35psi ), while the final pressure drop for the filter cartridge exchange is set at 2.5 bar. For the filter cartridge whose precision is lower than 10μm, the pressure drop for the filter cartridge exchange had better be set at 1.0 -1.5 bar (14.5 – 21.8psi).

TABLE 2

DIRT HOLD COMPARISON

TABLE 3

ORDERING INFORMATION

SF W 20- 5 P 63 P 28 JP W

A B C D

| SF | Brand name |

| W | Filter type- W= string wound, PP= melt blown, PPL= PP pleated, CTO= carbon block |

| A | Length- 10/20/30/40, inches. 250/500/750/1000, mm. |

| B | Rating- 0.5/1/3/5/10/25/50/75/100/150/200 microns |

| P | Yarn material- P= polypropylene, C= cotton, PE= polyester, GF= glass fiber |

| C | Outer diameter: 60/63/110/152 mm |

| P | Inner core material- P= polypropylene, S= stainless steel |

| D | Inner diameter- 28/30/70/100mm |

| JP | Series code- JP= JP series, HF= High Flow series |

| W | Additional info- W= washed pure material, L= pure pp yarn, BB= big blue |

NSF link

http://info.nsf.org/Certified/DWTU/Listings.asp?Company=C0243330&Standard=042

Raw material will be tested carefully assuring consistant quality. Following pictures are taken from our laboratory.