SFW standard PE/Rayon string wound filter cartridge

String wound filter cartridges made of PE or Rayon string, with stainless steel or tin plate core, use as high temperature liquid filter replacement such as palm oil filtering and soy oil filter.

Inquire Now

Specification

STRUCTURE

String wound filter cartridge consists of multi-hole frames wound closely with textile fibers. Diverse kinds of filtering precision can be realized by controlling the winding density. As the outer bore diameter is larger than the inner one, the filter cartridges have a good deep-level filtering capability. SFW standard series has competitive price and acceptable quality and stable performance. Instead of cotton, this series is made of PE string or Rayon string, with stainless steel or tin plate core, use as high temperature liquid filter replacement such as palm oil filtering and soy oil filter.

Sizes: 2.5"x10", 2.5"x20", 2.5"x30", 2.5"x40"

Inner core: SUS304, 201 stainless steel.

FEATURES

• Reasonable price

• Stable performance

MAIN TECHICAL SPECIFICATION

• Dimension: Outer diameter Ø63±1mm Inner diameter Ø 28mm or Ø 30mm

• Maximum operating Pressure: 0.5MPa (72.5psi)

• Maximum operating Temperature: Cotton 150℃(302℉), PE 130℃(266℉)

TYPICAL APPLICATIONS

• Cooking oil, palm oil, soy sauce (cotton or PE)

• Organic solvents (cotton only)

• Petroleum product (cotton only)

• Other applications

TABLE 1

FLOW OF FILTER CARTRIDGE

The recommended flow for the filter cartridges in service is shown in the table (L/h for a 250㎜filter cartridge)

Note:

1. The flow of each 250mm(10inch)filter cartridge should not exceed 1200 L/H (317G/H), otherwise its precision may be affected.

2. The flows shown in the above table are only the recommended values. The actual flow of the filter cartridge in service may change due to the liquid nature, temperature, the nature of the eliminated particles, the contents of the particles, etc.

3. It is recommended that a new filter cartridge used in the first time should work under a pressure drop of 0.1 - 0.3 bar (1.45 – 4.35psi ), while the final pressure drop for the filter cartridge exchange is set at 2.5 bar. For the filter cartridge whose precision is lower than 10μm, the pressure drop for the filter cartridge exchange had better be set at 1.0 -1.5 bar (14.5 – 21.8psi).

TABLE 2

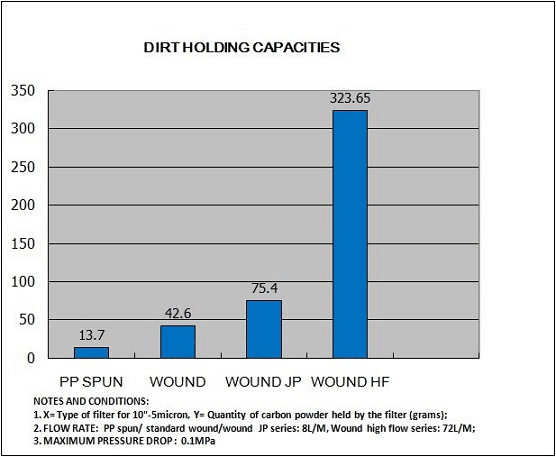

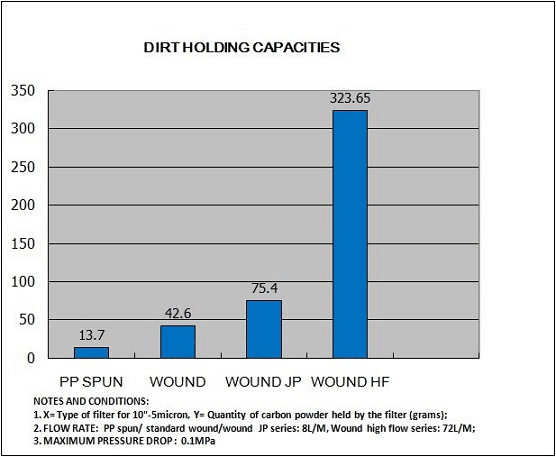

DIRT HOLDING CAPACITIES

TABLE 3

ORDERING INFORMATION

SF W 20- 5 C 63 S 28

A B C D

String wound filter cartridge consists of multi-hole frames wound closely with textile fibers. Diverse kinds of filtering precision can be realized by controlling the winding density. As the outer bore diameter is larger than the inner one, the filter cartridges have a good deep-level filtering capability. SFW standard series has competitive price and acceptable quality and stable performance. Instead of cotton, this series is made of PE string or Rayon string, with stainless steel or tin plate core, use as high temperature liquid filter replacement such as palm oil filtering and soy oil filter.

Sizes: 2.5"x10", 2.5"x20", 2.5"x30", 2.5"x40"

Inner core: SUS304, 201 stainless steel.

FEATURES

• Reasonable price

• Stable performance

MAIN TECHICAL SPECIFICATION

• Dimension: Outer diameter Ø63±1mm Inner diameter Ø 28mm or Ø 30mm

• Maximum operating Pressure: 0.5MPa (72.5psi)

• Maximum operating Temperature: Cotton 150℃(302℉), PE 130℃(266℉)

TYPICAL APPLICATIONS

• Cooking oil, palm oil, soy sauce (cotton or PE)

• Organic solvents (cotton only)

• Petroleum product (cotton only)

• Other applications

TABLE 1

FLOW OF FILTER CARTRIDGE

The recommended flow for the filter cartridges in service is shown in the table (L/h for a 250㎜filter cartridge)

| Micron Rate(μ m) | Viscosity | ||||

| 1cs(water) | 30cs | 60cs | 120cs | 250cs | |

| 0.5 | 70 | 60 | 40 | 25 | - |

| 1 | 150 | 90 | 60 | 40 | - |

| 3 | 300 | 120 | 80 | 50 | - |

| 5 | 500 | 170 | 120 | 60 | 45 |

| 10 | 800 | 300 | 140 | 70 | 60 |

| 20 | 1100 | 540 | 220 | 100 | 95 |

| 30 | 1200 | 670 | 300 | 150 | 130 |

| 50 | 1200 | 880 | 440 | 180 | 160 |

| 75 | 1200 | 1200 | 690 | 230 | 200 |

| 100 | 1200 | 1200 | 750 | 270 | 220 |

1. The flow of each 250mm(10inch)filter cartridge should not exceed 1200 L/H (317G/H), otherwise its precision may be affected.

2. The flows shown in the above table are only the recommended values. The actual flow of the filter cartridge in service may change due to the liquid nature, temperature, the nature of the eliminated particles, the contents of the particles, etc.

3. It is recommended that a new filter cartridge used in the first time should work under a pressure drop of 0.1 - 0.3 bar (1.45 – 4.35psi ), while the final pressure drop for the filter cartridge exchange is set at 2.5 bar. For the filter cartridge whose precision is lower than 10μm, the pressure drop for the filter cartridge exchange had better be set at 1.0 -1.5 bar (14.5 – 21.8psi).

TABLE 2

DIRT HOLDING CAPACITIES

TABLE 3

ORDERING INFORMATION

SF W 20- 5 C 63 S 28

A B C D

| SF | Brand name |

| W | Filter type- W= string wound, PP= melt blown, PPL= PP pleated, CTO= carbon block |

| A | Length- 10/20/30/40, inches. 250/500/750/1000, mm. |

| B | Rating- 0.5/1/3/5/10/25/50/75/100/150/200/250/300 microns |

| C | Yarn material- P= polypropylene, C= cotton, E= polyester, GF= glass fiber, Z=Rayon |

| C | Outer diameter: 60/63/110/152 mm |

| S | Inner core material- P= polypropylene, S= stainless steel |

| D | Inner diameter- 28/30/70/100mm |