String wound filter vs melt blown filter

String wound filter vs. melt blown filter

3 findings on the difference of string wound and melt blown filter on turbidity test

By Ian Ma

String wound filter and melt blown filter have many in common, both are norminal micron rated sediment filter, usually 100% polypropylene, similar size and connection types (DOE, SOE 222, SOE 226). They also fit similar applications, such as POU and POE water filters, sea water desalination, electro plating etc. They’re very similar and hard to choose, here we share our 3 findings of turbidity tests and hope it helps.

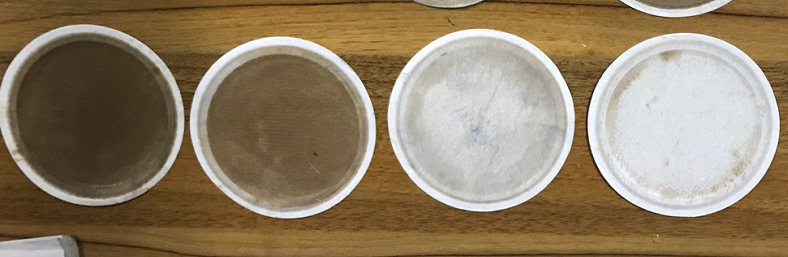

1.Effect of structure- the structure of string wound is multiple holes, wider from outside and narrower from inside, sediments can settle on in the holes according to their sizes. While melt blown doesn’t have gradual change holes, it relies on the fiber matrix to stop sediments. There’re designs with 3 or more graded micron layers to settle sediments separately named depth melt blown, but most of the depth melt blown filters have one problem- sudden change of pore size between one layer to another. When working on turbidity water, sediments tend to accumulate on the top of certain layer and block it quickly. (figure 1)

figure 1: sediment accumulating on certain layers disproportionately

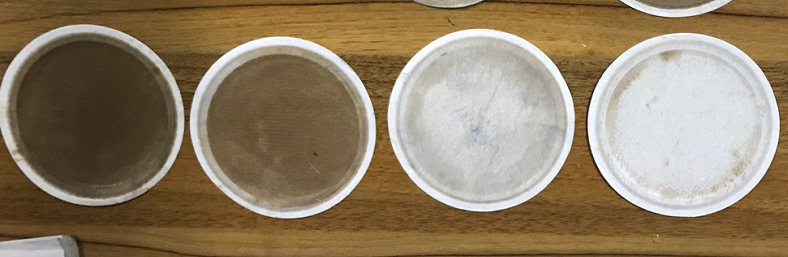

2.Removal efficiency- Judging by appearance, it’s natural to feel melt blown have higher efficiency than string wound because the fiber matrix on the melt blown looks denser than the apparent holes on the string wound. But in testing of turbidity reduction, we found JPL and JPW series string wound’s efficiency are 50% higher than most of melt blown filters, the tests were on the reduction rate of the A2 fine test dust from water (figure 2).

figure 2: A2 test dust on JPL series string wound and one of the top brand melt blown.

3.Micron control method- the pore size of string wound is controlled by the pattern of the string, usually the wider the gap between the strings the bigger the pore size. melt blown has 2 ways to control the pore size, one is by adjusting the diameter of the fiber, the other one which is more common is by changing the weight. After many turbidity tests on melt blown from 100g to 220g per 10” and found no noticeable difference between heavier and lighter filters, on the contrast we can see clear difference between 1micron and 5micron string wound. From these findings we can draw the conclusion of string wound filter vs. melt blown filter on turbidity testing as following table

References

JPL series string wound: JPL series string wound filter (sffilter.com.cn)

JPW series string wound: JPW series NSF certified string wound filter (sffilter.com.cn)

3 findings on the difference of string wound and melt blown filter on turbidity test

By Ian Ma

String wound filter and melt blown filter have many in common, both are norminal micron rated sediment filter, usually 100% polypropylene, similar size and connection types (DOE, SOE 222, SOE 226). They also fit similar applications, such as POU and POE water filters, sea water desalination, electro plating etc. They’re very similar and hard to choose, here we share our 3 findings of turbidity tests and hope it helps.

1.Effect of structure- the structure of string wound is multiple holes, wider from outside and narrower from inside, sediments can settle on in the holes according to their sizes. While melt blown doesn’t have gradual change holes, it relies on the fiber matrix to stop sediments. There’re designs with 3 or more graded micron layers to settle sediments separately named depth melt blown, but most of the depth melt blown filters have one problem- sudden change of pore size between one layer to another. When working on turbidity water, sediments tend to accumulate on the top of certain layer and block it quickly. (figure 1)

figure 1: sediment accumulating on certain layers disproportionately

2.Removal efficiency- Judging by appearance, it’s natural to feel melt blown have higher efficiency than string wound because the fiber matrix on the melt blown looks denser than the apparent holes on the string wound. But in testing of turbidity reduction, we found JPL and JPW series string wound’s efficiency are 50% higher than most of melt blown filters, the tests were on the reduction rate of the A2 fine test dust from water (figure 2).

figure 2: A2 test dust on JPL series string wound and one of the top brand melt blown.

3.Micron control method- the pore size of string wound is controlled by the pattern of the string, usually the wider the gap between the strings the bigger the pore size. melt blown has 2 ways to control the pore size, one is by adjusting the diameter of the fiber, the other one which is more common is by changing the weight. After many turbidity tests on melt blown from 100g to 220g per 10” and found no noticeable difference between heavier and lighter filters, on the contrast we can see clear difference between 1micron and 5micron string wound. From these findings we can draw the conclusion of string wound filter vs. melt blown filter on turbidity testing as following table

| Considerations | String wound filter | Melt blown filter |

|---|---|---|

| Service life and stability | Longer and more stable because of its gradual-change-hole structure. | Shorter and unstable because its uneven fiber matrix or sudden-change layer of matrix. |

| Efficiency on counter turbidity | 50% higher than average melt blown. | Lower than string wound. |

| Actual micron rate difference | Big difference from different rated microns because it’s controlled by pattern of the strings. | Little difference from 1 to 100micron. |

References

JPL series string wound: JPL series string wound filter (sffilter.com.cn)

JPW series string wound: JPW series NSF certified string wound filter (sffilter.com.cn)